Gain insights into proper vinegar manufacturing in The Philippines and how Philippine Aslam Corporation will save your business from the risks of fake vinegar.

By Lester Leonard P. Antonio

Business Development Intern

Arc Innovation and Insights

A staple of any household, vinegar is the most versatile condiment in the world. This sour liquid is a pickling agent, flavor enhancer, preservative, and dip, among other things. Its versatility even goes beyond the kitchen. In its concentrated state, vinegar is an ingredient in common industrial cleaners and disinfectants, proving that vinegar is a commodity worth millions.

Like any popular and sought-after product, fakes will come into the picture. Its primary purpose is to disrupt the market by giving consumers a cheaper version of the real thing. However, fakes can be quite dangerous, especially ones we use for food.

Vinegar is no exception to fakes. As surprising as that may sound, that is the reality. ‘Fake’ vinegar in The Philippines has proliferated since the 1970s. The Philippine Food and Drugs Administration (FDA) released a guideline for vinegar manufacturers in the Philippines to protect the public from ‘fake’ vinegar.

However, despite the government’s clamp-down on fake vinegar, The Philippine vinegar manufacturing industry is still murked with illegally produced vinegar.

In June 2019, The FDA released a list of locally-produced vinegar brands using synthetic acetic acid. Five brands tested positive for artificial matter from the 39 local vinegar brands subjected to Permanganate Oxidation Number (PON) testing.

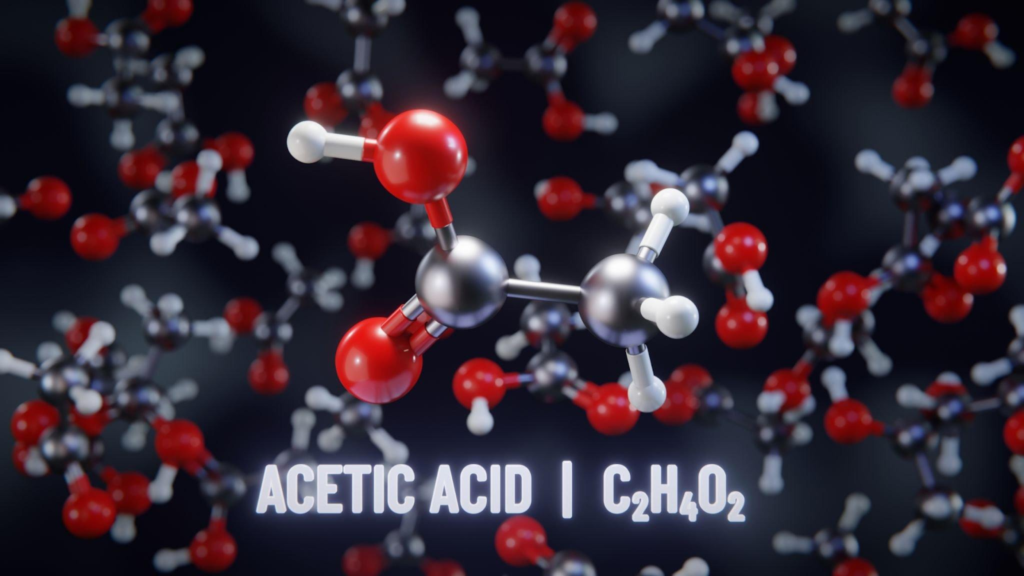

The Main Component of Vinegar: Acetic Acid

Before diving into fake vinegar, we must note that vinegar only has two components: water and acetic acid. Acetic acid gives the vinegar its signature sourness and pungent odor. Traditionally produced through fermentation, acetic acid is a by-product of yeast feeding on the sugar or starch of plant-based products, which turns into alcohol. The alcohol produced will be exposed to oxygen to make the Acetobacter (the bacteria present in the broken-down sugars) further ferment the liquid, turning it into acetic acid.

The fermentation process of vinegar can take anywhere from a few weeks to a few months. However, with advancements in chemistry, chemists developed acetic acid production without the tedious fermentation process. That product produced from inorganic compounds is widely known as glacial acetic acid.

Glacial Acetic Acid and Why It’s Fake Vinegar

Glacial acetic acid is also known as ethylic acid, vinegar acid, and methane carboxylic acid. The term “glacial” came from its icy crystal appearance, which forms at 16.6° Celsius. In terms of chemical structure, fermented acetic acid and glacial acetic acid are the same. However, the difference lies with the raw materials. Fermented acetic acid comes from plant-based products, while the glacial variety is from chemicals.

The development of glacial acetic acid paved the way for the industrial use of vinegar’s base component. Production of rubber, wood glue, pesticides, dyes, and ink all use glacial acetic acid over its fermented counterpart. Its cheaper cost and quicker production process made glacial acetic acid the choice for non-food industries.

However, for the same reasons, a handful of vinegar manufacturers in the Philippines use glacial acetic acid as their base component. Sure, it’s more economical than fermented acetic acid, but Philippine vinegar manufacturing has restrictions as dictated by the FDA.

By law, using the glacial variant for vinegar is illegal. Production of vinegar in The Philippines should only use fermented acetic acid. It has been so since 1970 as required by the Food and Drug Administration through its Administrative Order No. 134, series of 1970.

Regulation Prescribing the Standard of Identity and Quality of Vinegar

The Secretary of Health from 1969-1971, Dr. Amadeo H. Cruz, issued FDA Administrative Order No. 134 to end the proliferation of ‘fake’ vinegar in The Philippines. In the memo, vinegar, regardless of variety (sugarcane, malt, coconut, pineapple, or nipa-sap), should be produced by alcoholic or acetous fermentation.

Moreover, the memo specifically stated that the FDA would consider vinegar containing synthetic acetic acid and cloudifying agents adulterated and would prohibit its sale.

So how will the public know if they’re purchasing fermented vinegar?

The truth is, identifying fake vinegar from the fermented variety can be difficult since they look very much alike. Some vinegar manufacturers in the Philippines attempt to cut costs by alternating between glacial and fermented acetic acid in their production processes. This practice makes it difficult for consumers to differentiate between the two. However, by partnering with a reputable vinegar manufacturer like Philippine Aslam Corporation, businesses can ensure they avoid the risks associated with glacial acetic acid and keep the quality of their products.

Philippine Aslam Corporation is the largest vinegar manufacturer in the Philippines, supplying high-quality vinegar in Southeast Asia. Hundreds of client partners trust Aslam’s all-natural Cane Vinegar, Sukang Iloko, and Coconut Tuba.

Talk to us today and reap the benefits of partnering with Philippine Aslam Corporation. The only vinegar manufacturer in the Philippines that prides itself on its highest quality vinegar products that meet the FDA’s strict standards. Contact us today and be the next Aslam client-partner.